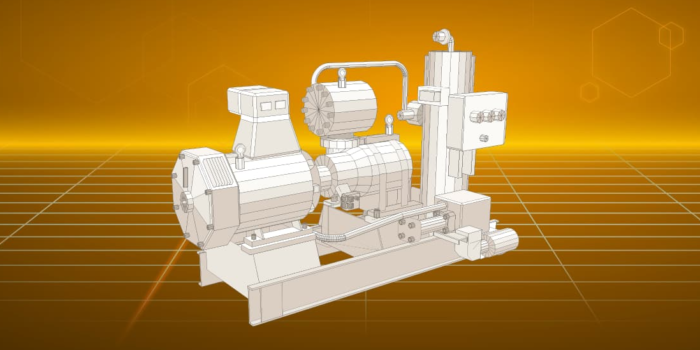

A compressor is a device whose main purpose is to increase air pressure. The entire work process of the compressor is focused on energy conversion. In the first stage, electrical energy from the grid is converted into kinetic energy of the shaft movement that drives the compressor block. In the second stage, this energy is converted into compressed gas energy due to the thermodynamic transformation. A compressor is a device that generates a huge amount of heat, therefore each device should be equipped with a cooling system to prevent overheating of the device.

Reciprocating compressors - the most common device on the market in the category of equipment with small and medium capacities. They are used in particular in the automotive industry. They are not suitable for work in the food industry due to the fact that the blown air is heavily polluted. Another disadvantage of reciprocating compressors is their noisy operation. This noise can sometimes be nuisance and harmful to health.

Screw compressors - these are devices perfectly suited to work in harsh conditions. They are used in many industries, such as the pharmaceutical, wood, food, machine and electronic industries. The advantages of screw compressors include: high durability, quiet operation, modernity and energy efficiency, simple operation and more favorable requirements in relation to technical inspections. Screw compressors, like reciprocating compressors, also blow off oil-contaminated air, but the contamination is much lower than with reciprocating compressors. Screw compressors generate large amounts of heat during operation, which is why they are also used for space heating.

Centrifugal compressors are dynamic compressors. They are perfect for works requiring immaculately clean air. These devices are oil-free, and their structure ensures that the air and lubricants are properly separated.

Based on the pressure ratio, the following are distinguished:

- Fans

- Blowers

- Compressors

Based on the compressor gradation criterion, we divide them into:

- Single stage compressors

- Two-stage compressors

Based on the mobility criterion, compressors are divided into:

- Portable compressors

- Stationary compressors

Based on the type of compressor drive, we divide into:

- Electric compressors

- Hand compressors

Based on the type of compressed medium, the compressors are divided into:

- Gas compressor

- Air compressor

How to get permission?

In order to obtain the appropriate qualifications for compressors, you should use the courses available on the market. Below we present one of them: a course in compressors, compressors, suction nozzles, blowers and compressed air installations. The course is conducted by us in cities such as: Częstochowa, Bełchatów, Gliwice, Wrocław, Łódź, Opole, Katowice, Warsaw, Kraków, Poznań, Gdańsk, Toruń, Bielsko Biała, Bydgoszcz, Olsztyn, Białystok, Szczecin, Zielona Góra, Rzeszów , Lublin, Kielce. In order to find out about the current date of conducting the course and to register for the course, please visit our website, where you will find the schedule with all the necessary information. The conditions that must be met by the candidate are primarily 18 years of age and minimum elementary education. The course on compressors, compressors, fans, blowers and compressed air installations was divided into two parts, namely the theoretical part and the practical part. Completion of the course is associated with admission to the examination before the qualification committee. After passing the exam, the trainee receives the compressor qualifications issued in the form of a qualification certificate. Permissions are valid for 5 years from the date of issue and are subject to renewal.